Scan Tech Surveys

When It Comes to Solutions!

Scan Tech Surveys

When It Comes to Solutions!

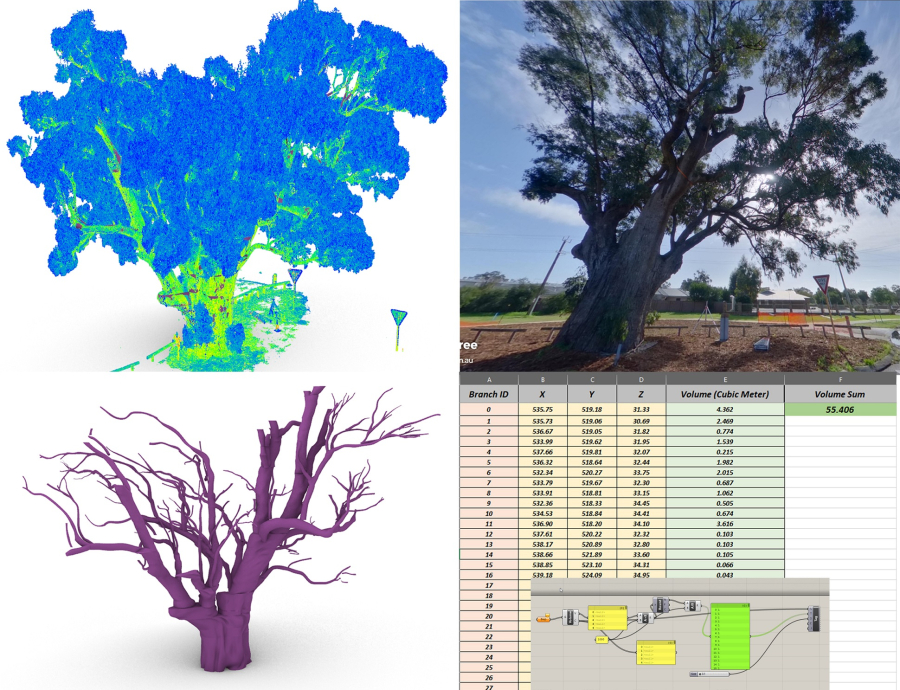

3D Scanning of Tree and Calculating Volume of Branches

Using 3D scanning technology to calculate the volume of tree branches can offer several benefits in various applications, including forestry management, environmental research, and urban planning. Here are some advantages of using 3D scanning for this purpose:

-

Accurate Volume Calculation: 3D scanning provides a highly accurate way to measure the volume of tree branches. This precision is important for making informed decisions about tree health, biomass estimation, and resource allocation.

-

Non-Intrusive Method: Traditional methods of measuring tree volume, such as felling the tree and sectioning its branches, can be destructive and harmful to the environment. 3D scanning allows for non-intrusive measurements, which preserves the tree and its ecosystem.

-

Efficiency: 3D scanning technology is relatively quick and efficient. It can capture a detailed 3D model of the tree's branches in a short amount of time, saving labor and resources compared to manual measurements.

-

Data Visualization: The 3D models generated from scanning can provide visual representations of the tree's structure, allowing researchers and decision-makers to better understand the branching patterns and overall health of the tree.

-

Biomass Estimation: Accurate volume calculations from 3D scanning can help estimate the biomass of the tree's branches. This information is valuable for assessing carbon sequestration potential, fuelwood availability, and other ecological considerations.

- Preservation from falling: In case the tree is old (like this example), 3D scanning helps structural engineering to come up with accurate design regards with designing proper rated scaffolding or steel structure to preserve the tree to crack down and falling apart.

3D laser scanning is the most efficient mthod to calcualte the volume of a tree via 3D modeling process.

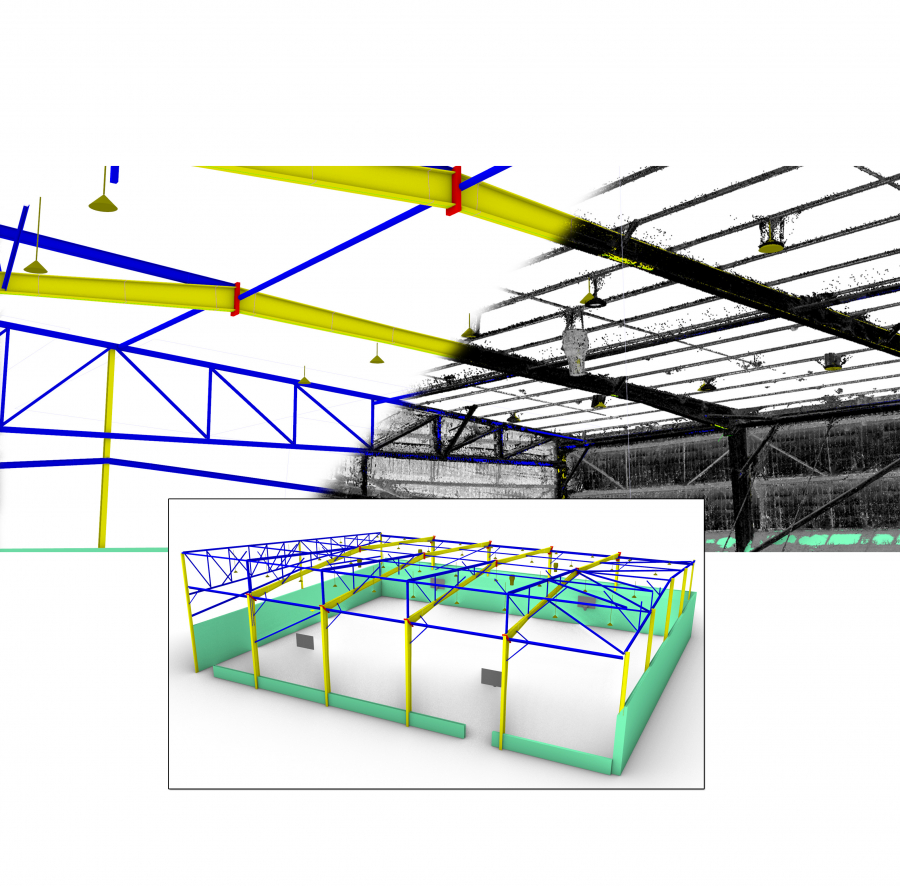

3D Scan of Steel Structure

3D scanning of steel structures offers numerous benefits across various industries. Here are some of the key advantages:

-

Accurate As-Built Documentation: 3D scanning provides precise and detailed as-built documentation of steel structures. This information is valuable for renovation, maintenance, and retrofitting projects, as it ensures that new components or modifications fit perfectly into existing structures.

-

Time and Cost Savings: Traditional manual measurement methods can be time-consuming and labor-intensive, especially for complex steel structures. 3D scanning significantly reduces the time required to capture data, leading to cost savings in terms of labor and project timelines.

-

Non-Destructive Data Collection: 3D scanning is a non-contact and non-destructive technology. It does not require physical contact with the structure, preventing any potential damage that could occur with conventional measurement techniques.

-

Improved Safety and Risk Reduction: By minimizing the need for human intervention in hazardous environments, 3D scanning contributes to improved safety for workers. It also reduces the risk of errors or inaccuracies that might lead to safety issues in the future.

-

Enhanced Design and Analysis: The accurate 3D data obtained from scanning allows engineers and designers to conduct simulations and analyses more effectively. This capability enables them to identify potential structural weaknesses, analyze load-bearing capacities, and make informed decisions during the design phase.

-

Facilities Management and Maintenance: 3D scanning aids in facilities management by providing an up-to-date digital model of the steel structure. Maintenance teams can use this model to plan maintenance schedules, identify areas that need repair, and optimize asset management.

-

Visual Communication and Collaboration: 3D scanning generates detailed visual representations of steel structures. These visuals help stakeholders, including clients, architects, engineers, and construction teams, to better understand the project, leading to improved collaboration and decision-making.

-

Preservation of Historical Structures: For historic steel structures, 3D scanning offers a way to preserve their architectural and engineering heritage. By creating accurate digital records, restoration efforts can be more precise, ensuring the structure's integrity is maintained.

-

Quality Control and Inspection: 3D scanning enables comprehensive quality control and inspection processes. By comparing the scanned data with design specifications, deviations and defects can be identified early, reducing the likelihood of construction errors.

-

Integration with Building Information Modeling (BIM): 3D scanning seamlessly integrates with BIM workflows. The scanned data can be directly incorporated into BIM models, improving the accuracy and completeness of the information available for construction and facility management.

Overall, 3D scanning of steel structures revolutionizes the way construction, maintenance, and engineering projects are undertaken. Its ability to capture accurate data quickly and efficiently empowers professionals to make informed decisions, leading to safer, more cost-effective, and well-executed projects.

We always use the right tools for your specific applccations.

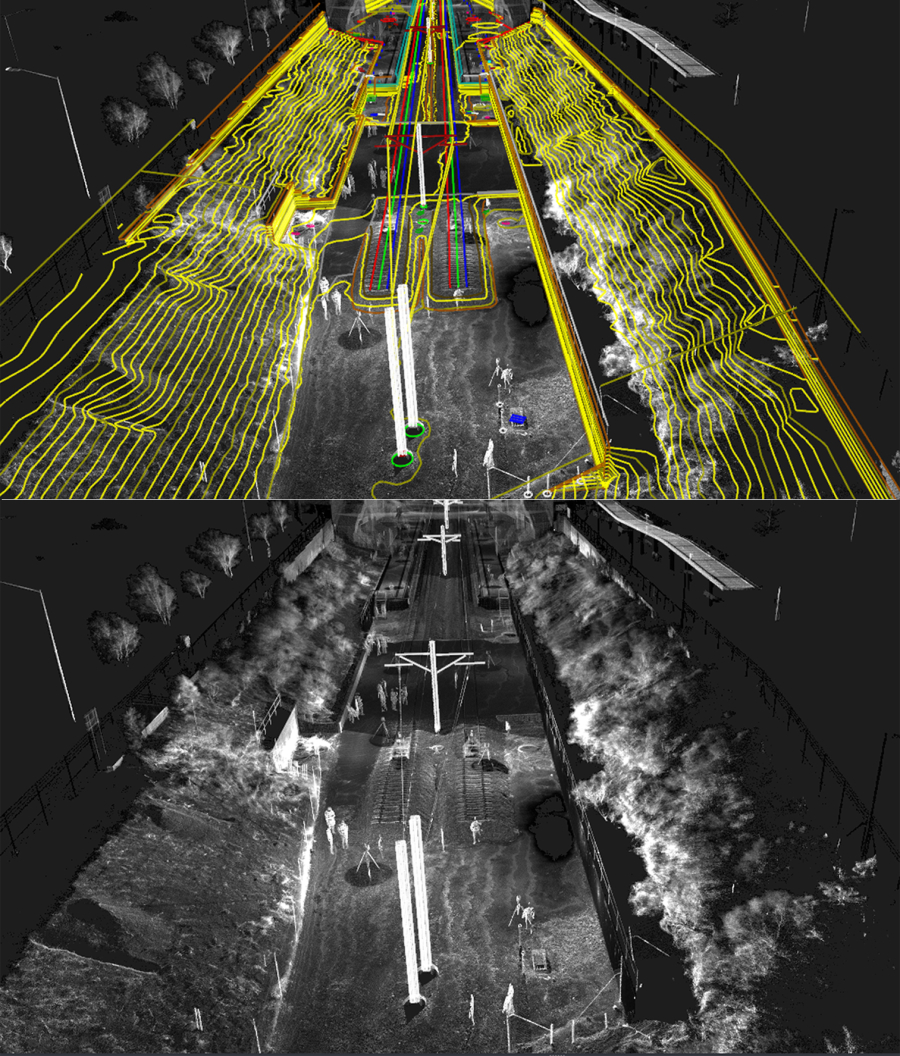

Detail Survey of Rail Corridor

Railway feature extraction from point clouds involves the process of analyzing and identifying specific railway-related elements and structures within a three-dimensional point cloud dataset. Point clouds are dense sets of 3D coordinates representing the surface of an object or environment, obtained through various methods such as laser scanning or photogrammetry.

Here are some common railway features that can be extracted from point cloud data:

-

Rail tracks: Rail tracks are a fundamental component of a railway system. Extracting rail tracks from point clouds involves identifying the geometric pattern formed by the rails and their alignment. This information is crucial for tasks like track maintenance, alignment verification, and clearance analysis.

-

Railway switches and crossings: Switches and crossings allow trains to change tracks or cross from one track to another. Identifying these features in point cloud data involves detecting and characterizing the complex geometry of the switch points, frogs, and guardrails. Accurate extraction of switches and crossings aids in maintenance planning and safety assessments.

-

Overhead line equipment (OLE): Overhead line equipment includes catenary wires, masts, and other components that supply power to electric trains. Extracting OLE features from point clouds involves identifying the wires, poles, and other supporting structures. This information is essential for assessing the clearance between the OLE and passing trains.

-

Signal gantries and poles: Signal gantries and poles support the signaling system along the railway tracks. Extracting these features from point clouds involves identifying the supporting structures and signal heads. This information is crucial for maintenance planning, assessing visibility, and signal positioning.

-

Platform edges: Platform edges are critical for passenger safety and accessibility. Extracting platform edges from point cloud data involves identifying the elevated structure along the track where passengers board and alight. Accurate extraction of platform edges aids in analyzing platform gaps and planning modifications for accessibility compliance.

-

Trackside structures: Various structures, such as bridges, tunnels, and retaining walls, exist along railway lines. Extracting trackside structures from point clouds involves detecting and characterizing these objects, which helps with structural assessments, maintenance planning, and clearance analysis.

To extract these railway features from point cloud data, various techniques can be employed, including point cloud segmentation, classification algorithms, and geometric modeling. These techniques leverage the geometric and spatial properties of the point cloud data to identify and extract specific features of interest. Additionally, combining point cloud data with other sources, such as imagery or GIS data, can enhance the accuracy and efficiency of feature extraction processes.

We promise quality on every aspect of our delievrbales and we are specilaised in rail details surveys

Light Weight Carbon Fibre Tripod for Leica P50

Fieldwork often involves traveling to different locations, and portability becomes crucial. Carbon fiber tripods are designed with lightweight materials and compact folding mechanisms, making them easy to carry and transport. Quick-release leg locks and intuitive setup mechanisms allow for rapid deployment, saving valuable time on-site.

When it comes to laser scanning, the choice of tripod plays a significant role in achieving precise and reliable results. Carbon fiber lightweight tripods offer the perfect combination of stability, portability, and durability, making them an excellent choice for laser scanning applications. With their ability to dampen vibrations, customizable height options, and easy setup, these tripods enhance the efficiency and accuracy of laser scanning projects. Invest in a carbon fiber lightweight tripod, and experience the benefits of enhanced precision and portability in your laser scanning endeavors.

Quicker and Lighter with Scan Station P50

Mobile 3D Scanning Technology (Slam)

We are proud to announce that we have recently added Slam technology to our 3D Scanning equipment fleet. This gives us the ability to acquire large areas in a very quick time turnaround. Below is an example of a 250 m road section registered in PCG2020 and AHD datum. Based on captured point cloud a detailed survey can be accomplished.

We can also capture panorama imagery during the scan field capture. The imagery is essentially used for the colorization of the scan data and also for the interpretation of the data for feature extraction.

The scanner can be mounted on an extension pole which is perfect for ceiling void 3D Scans.

We apply right hardware and software for the right application. Our core vlaue is produce high qulity delievrbales.

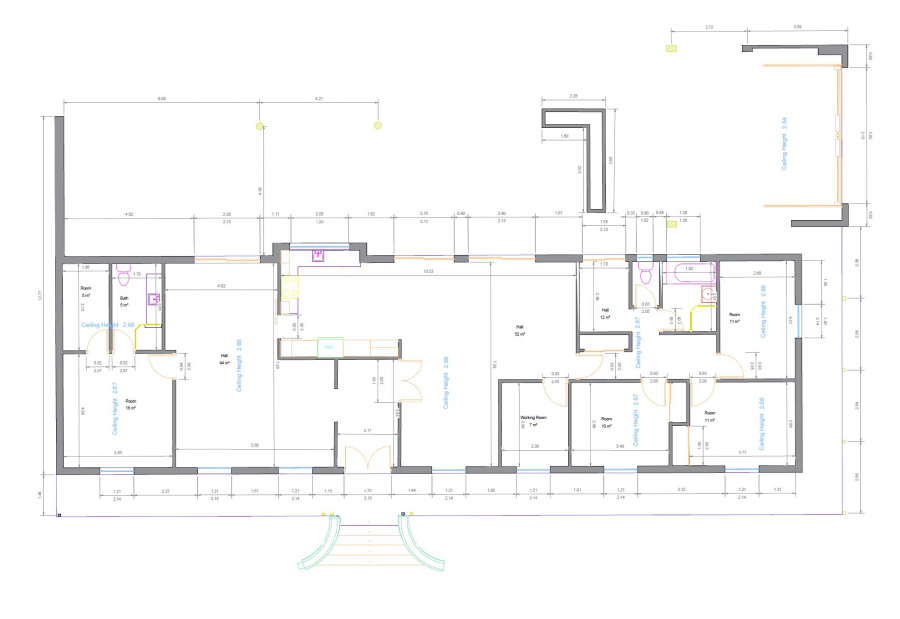

2D Floor Plan

The most efficient and quickest way of creating floor plans from an existing building, especially old ones, is by utilizing 3D scanning technology. It gives you all the details in one go! No need to go back and add information like windows' height, ceiling heights, and lots of other details that could be missed in conventional methods.

Do not think of using any other methodologies than 3D Laser Scanning when you are revovating a house. Get the drawings done proprly as they are the base of any other work to be carried on.

2D Floor Plan

The most efficient and quickest way of creating floor plans from an existing building, especially old ones, is by utilizing 3D scanning technology. It gives you all the details in one go! No need to go back and add information like windows' height, ceiling heights, and lots of other details that could be missed in conventional methods.

Do not think of using any other methodologies than 3D Laser Scanning when you are revovating a house. Get the drawings done proprly as they are the base of any other work to be carried on.

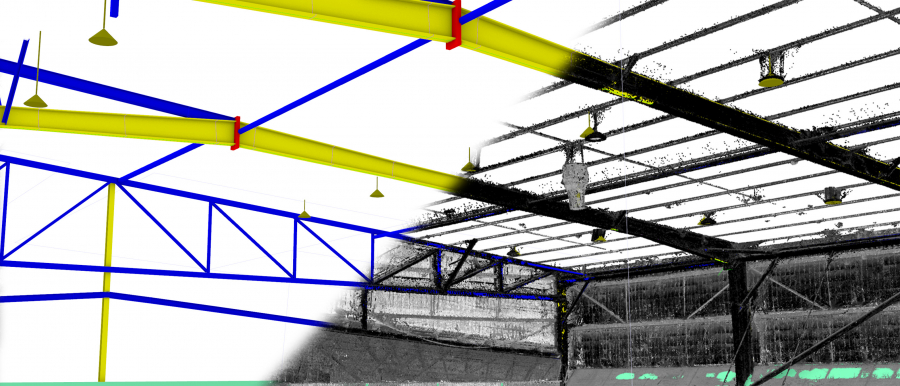

3D As-built of Structure

The main component to begin within a design project for an existing structure is seeking accurate drawings. 3D Laser Scanning is the best approach to follow for this purpose. Our team has completed the 3D model of this structure for design purposes.

3D Scanning Technology is the most accurate and cost-effective of making 3D-Asbult from existing structures.

3D Scanning Technology is the most accurate and cost effective of making 3D-Asbult from existing structures.

3D As-built of Strcuture

The main component to begin within a design project for an existing structure is seeking accurate drawings. 3D Laser Scanning is the best approach to follow for this purpose. Our team has completed the 3D model of this structure for design purposes.

3D Scanning Technology is the most accurate and cost-effective of making 3D-Asbult from existing structures.

3D Scanning Technology is the most accurate and cost effective of making 3D-Asbult from existing structures.

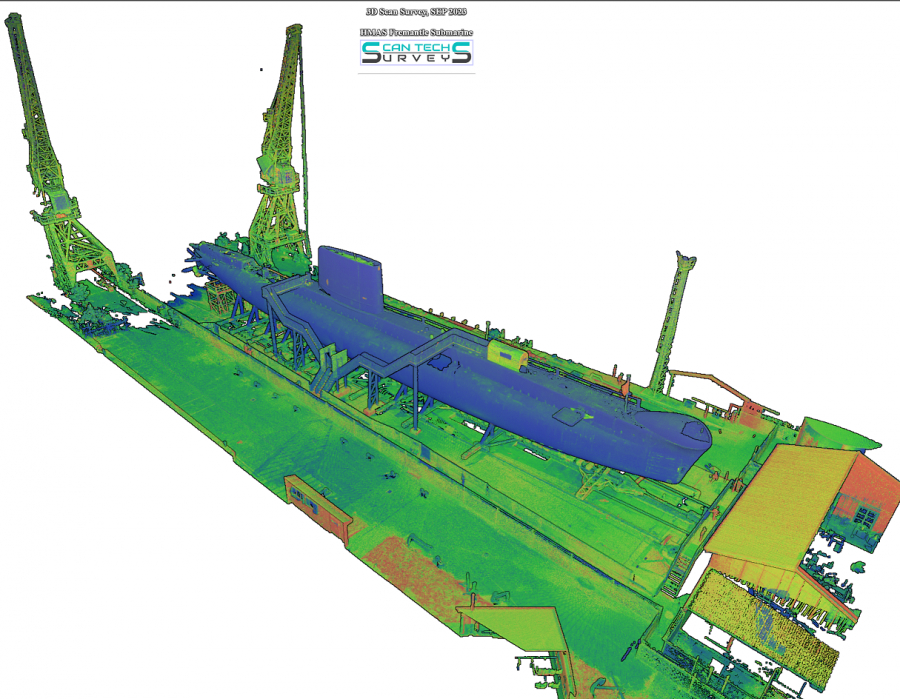

Scaffolding Planning

Our smart client recently reached out to get this historic submarine 3D scanned for the purpose of planning their scaffolding project. This can save them lots of execution time in the field and eventually save a lot of money for them. 3D Scanning technology can help various industries deal with spatial data and make their process much more efficient. This technology is the most efficient and cost-effective for accurate and reliable spatial data capture.

Utilising 3D Laser Scanning Technolgy for planning and descion making can help engineers and designers to be a better decsion maker.